Méta-description :Vous avez des difficultés à choisir le grammage idéal pour les non-tissés spunbond ? Ce guide de Fuzhou Henghua New Material Co., Ltd. vous aide à trouver le grammage parfait pour votre application, en équilibrant résistance, fonctionnalité et coût.

Choisir le bon grammage (GSM – grammes par mètre carré) pour votre tissu non tissé spunbond est l'une des décisions les plus importantes et les plus fréquentes que vous aurez à prendre. Un bon choix vous garantit un produit performant et économique. À l'inverse, un mauvais choix peut entraîner des problèmes de durabilité, de fonctionnalité ou des dépenses inutiles.

ÀFuzhou Henghua Nouveau Matériau Co., Ltd.Nous comprenons ce dilemme. En tant que fabricant professionnel de tissus non tissés spunbond, nous sommes là pour simplifier le processus de sélection. Ce guide vous aidera à trouver le juste équilibre entre coût et performance.

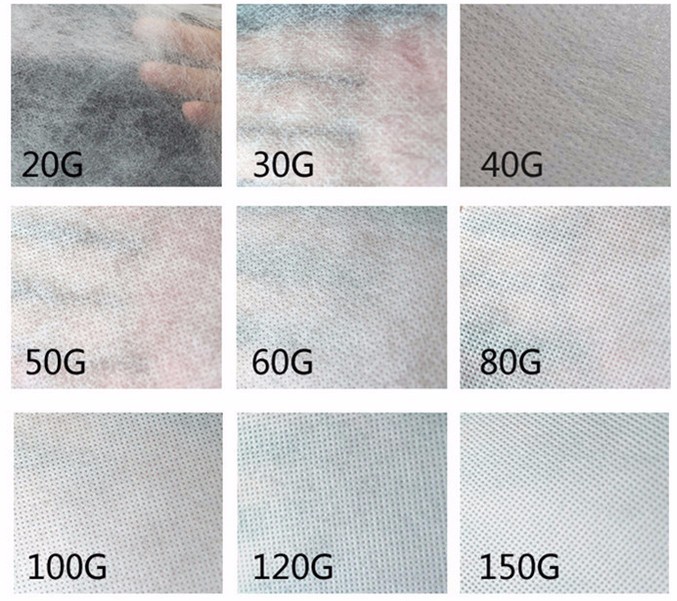

Comprendre le poids en grammes : tout est question de densité

En termes simples, le grammage (en grammes) mesure la masse du tissu par unité de surface. Un grammage plus élevé signifie généralement :

Épaisseur accrueet opacité

résistance à la traction supérieureet la force de déchirure

Durabilité amélioréeet propriétés de barrière

Coût des matériaux plus élevépar mètre carré

Un GSM plus faible signifie :

Choisir le poids en grammes adapté à votre application : un guide pratique

Voici un aperçu des gammes GSM courantes et de leurs utilisations idéales :

1. Léger (10 – 25 GSM)

Utilisations typiques :Couche de parement pour produits d'hygiène féminine (protège-slips, serviettes hygiéniques légères), lingettes jetables, emballages légers, doublures.

Pourquoi:Offre une douceur, une absorption des fluides et une respirabilité exceptionnelles, tout en minimisant la quantité de matière utilisée et les coûts. Idéal pour les applications où le contact direct avec la peau et le confort sont primordiaux.

2. Poids moyen (25 – 60 GSM)

Utilisations typiques :Tissus médicaux (blouses chirurgicales, champs opératoires, draps), doublures de meubles, protège-matelas, géotextiles pour la lutte contre l'érosion, couvertures agricoles (protection contre le gel, lutte contre les mauvaises herbes).

Pourquoi:Cette gamme est la plus polyvalente. Elle offre un excellent compromis entre résistance, propriétés de barrière et coût. Les tissus de cette gamme sont suffisamment résistants pour les EPI médicaux à usage unique ou les applications agricoles de moyenne intensité.

3. Grammage élevé (60 – 150+ GSM)

Utilisations typiques :Géotextiles haute résistance, supports de moquette, lingettes industrielles, sacs de courses résistants, intérieurs automobiles et supports de revêtement.

Pourquoi:Privilégiant une résistance, une stabilité et une durabilité maximales, ces tissus sont conçus pour les environnements exigeants où la résistance aux contraintes mécaniques et la performance à long terme sont essentielles.

Au-delà du GSM : la prise en compte du coût total

Bien que le prix au mètre carré augmente avec le GSM, il est crucial de réfléchir àCoût total de possession.

Un tissu légèrement plus épais pourrait-il convenir ?Prolonger la durée de vie du produit ou prévenir les pannes, et ainsi réaliser des économies à long terme ?

Un tissu légèrement plus léger pourrait-il convenir ?tout aussi efficace, tout en réduisant les coûts des matières premières et le poids des expéditions ?

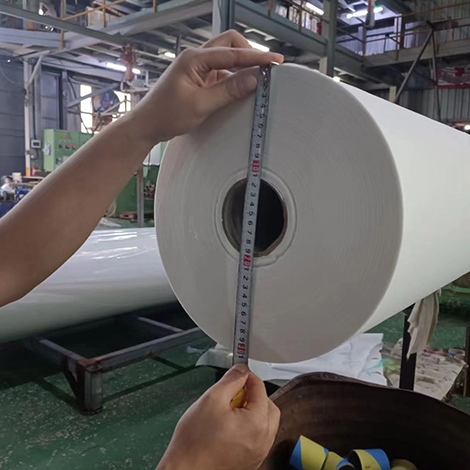

Cohérence des performances :Choisir un fabricant fiable commeFuzhou HenghuaVous avez ainsi la garantie que le grammage commandé correspondra à celui que vous recevrez, avec des variations minimales sur l'ensemble du rouleau et entre les lots. Cette constance prévient les problèmes de production et le gaspillage dans votre usine.

Votre prochaine étape : faites appel à un expert

Le meilleur choix dépend de vos machines, des exigences relatives au produit final et de votre budget. C'est là que la théorie rencontre la pratique.

Chez Fuzhou Henghua New Material Co., Ltd., nous ne vendons pas seulement du tissu ; nous fournissons des solutions.Notre équipe technique peut vous aider à analyser vos besoins et à vous recommander le poids en grammes optimal, la largeur et tous les additifs nécessaires (comme la résistance aux UV ou le traitement hydrophile).

Prêt(e) à trouver votre partenaire idéal(e) ?

Contactez notre équipe commercialeavec les détails de votre candidature.

Demandez des échantillons gratuitsdes différentes options GSM à tester sur votre équipement.

Obtenez un devis personnaliséen fonction des besoins spécifiques de votre projet.

Laissez-nous vous aider à prendre une décision éclairée qui optimise à la fois la performance et la rentabilité.

Contactez Fuzhou Henghua New Material Co., Ltd. dès aujourd'hui pour votre solution de non-tissé spunbond !